Box Compression Tester provides a reliable and precise way to test the strength of your boxes and packaging materials.

What is a Box Compression Tester?

A Box Compression Tester is a machine designed to assess the compressive strength of boxes made from materials like corrugated cardboard. It applies controlled pressure to a box, simulating the weight and forces it would encounter during shipping, stacking, and storage. The tester measures the point at which the box deforms or collapses, helping manufacturers determine whether their packaging is strong enough to withstand real-world conditions.

By using a Box Compression Tester, businesses can identify the performance limits of their packaging, ensuring that boxes can safely support the weight and handling they will endure during the supply chain process.

Why is Box Compression Testing Important?

The strength of your packaging directly affects product safety and overall customer satisfaction. Inadequate packaging can lead to damaged goods, dissatisfied customers, and costly returns. Here's why Box Compression Testing is essential:

Prevents Product Damage: If a box is not strong enough, it can collapse under pressure, resulting in damaged products. By using a Box Compression Tester, you ensure that your packaging protects your products throughout the supply chain.

Compliance with Industry Standards: Many industries have packaging standards in place to ensure the strength and durability of packaging materials. Testing your boxes against standards like ASTM D642 and ISO 12048 ensures compliance and prevents potential issues with regulations.

Cost Savings: Stronger packaging minimizes the risk of product damage, reducing the need for replacements and returns. It also helps optimize packaging materials, ensuring they are used efficiently without waste.

Improves Packaging Design: Regular testing helps improve packaging design by identifying weaknesses and ensuring boxes are both cost-effective and strong enough to meet performance expectations.

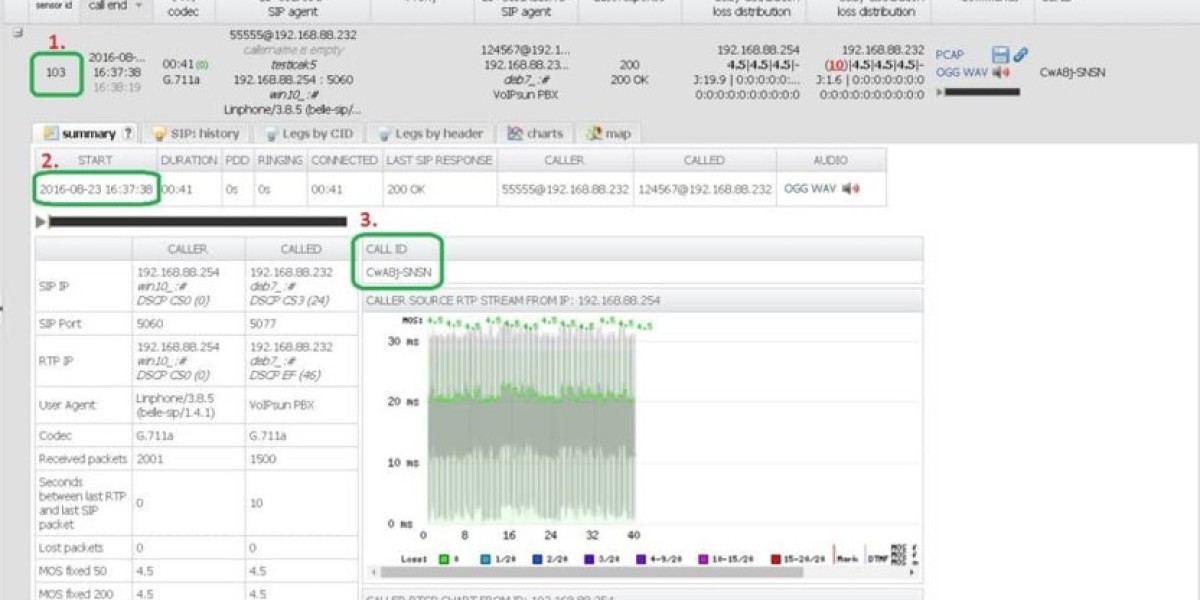

How Does a Box Compression Tester Work?

Pacorr's Box Compression Tester applies pressure to the box until it either deforms or collapses. The test simulates real-world conditions where boxes are stacked or subjected to pressure during transportation and handling.

Here’s how the Box Compression Tester works:

Edge Crush Test (ECT): Measures the strength of the edges of the box, giving insight into how well the box will perform when stacked under pressure.

Flat Crush Test (FCT): Tests how well the box holds up when pressure is applied to its flat surfaces.

Bursting Strength: Evaluates how the box handles internal pressure, which is important for ensuring that the box holds its shape during handling and storage.

These tests provide vital information about the strength of your packaging, enabling you to make the necessary adjustments to improve its performance.

Key Features of Pacorr’s Box Compression Tester

Accurate Results: Our Box Compression Tester Price provides precise measurements, ensuring reliable data for packaging quality control.

User-Friendly: Designed for ease of use, the tester’s intuitive interface minimizes the learning curve and reduces downtime, making it easy for your team to conduct tests efficiently.

Meets Global Standards: The tester is built to comply with international standards like ASTM D642 and ISO 12048, ensuring your packaging is ready for global shipping and handling requirements.

Detailed Reporting: The system generates detailed reports that help you analyze test results and identify areas for improvement in your packaging design.

Applications of Box Compression Testing

Manufacturers: For businesses producing packaging materials, such as corrugated boxes, Box Compression Testers ensure that their products meet the required strength standards.

Shipping and Logistics: Companies involved in shipping use compression testing to verify that their packaging can withstand the rigors of transportation, reducing the risk of damage.

Packaging Design: Designers of custom packaging use Box Compression Testers to test prototypes and make necessary adjustments before production, ensuring the packaging performs well in real-world conditions.

Retail: Retailers can use compression testing to ensure their packaging can handle the stress of being stacked or handled by customers without collapsing or breaking.

Conclusion

A Box Compression Tester is an invaluable tool for businesses involved in packaging. It helps ensure that your boxes are strong enough to protect your products during transit, preventing damage and improving customer satisfaction. At Pacorr Testing Instruments, we offer high-quality Box Compression Testing that can help you optimize packaging strength, reduce costs, and comply with industry standards.

By investing in a Box Compression Tester from Pacorr, you ensure the reliability and safety of your packaging, ultimately leading to a better experience for your customers. For more information, visit pacorr.com and discover how we can help you improve your packaging quality.